CUSTOM ROLL FORMING | A MANUFACTURER’S GUIDE TO COST CONTROL

Given the many metal forming processes available today, custom roll forming steel may be one of the most cost-effective.

In this guide, we’ll look at the ins and outs of metal roll forming costs:

- Partnering with a Roll Forming Company Vs. In-House Forming

- How Roll Forming Limits Your Total Manufacturing Cost of Ownership

- 3 Factors that Affect Roll Forming Costs

- How to Cut Roll Forming Costs with Efficiency

- How to Reduce Raw Material Cost? Ask Your Roll Forming Company

- The Case for Vendor Managed Inventory

- Beyond Costs: Roll Forming Advantages & Values

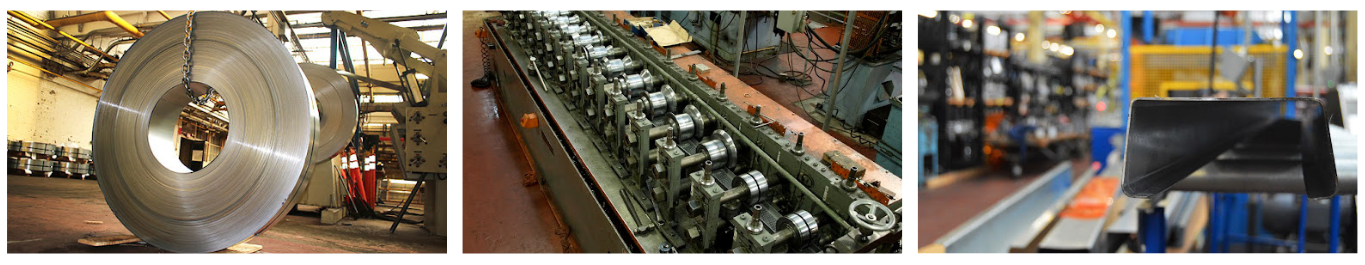

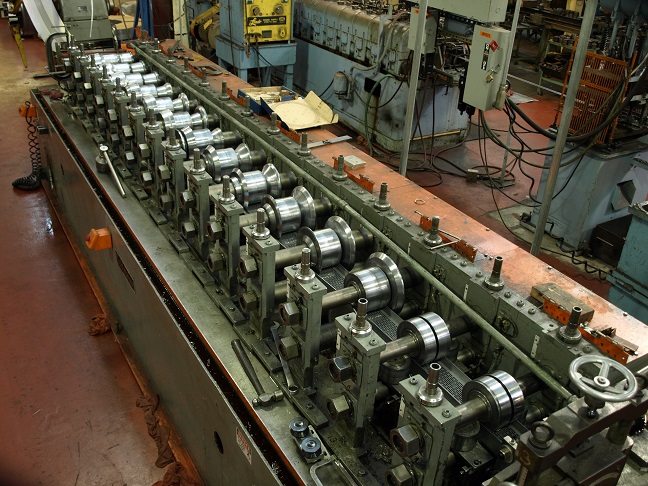

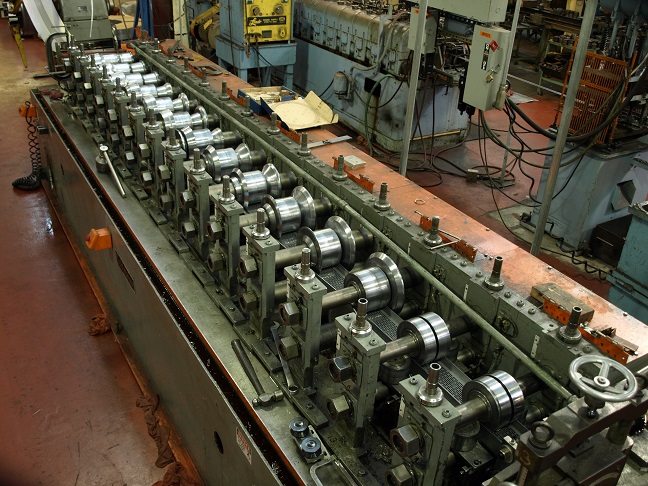

In roll forming, a machine pulls a coiled strip through a sequence of roll dies, gradually manipulating the metal into your desired cross-sectional shape.

So why do companies choose roll formed steel over other manufacturing methods like extrusion or casting?

Metal roll forming systems offer distinct part production advantages:

- Speed

- In-line punching or notching

- Economy of scale

- The ability to produce long shapes that wouldn’t fit in a brake press

- Customization

Seeing these advantages, some companies choose to purchase their own roll form machine and manufacture parts in-house. Others see the value in partnering with a custom roll forming corporation to meet their requirements.

Partnering with an experienced roll forming company is a great way to improve operational efficiency in manufacturing while reigning in costs.

PARTNERING WITH A ROLL FORMING COMPANY VS. IN-HOUSE FORMING

Bringing roll forming processes into your plant is more than just buying a machine that you run when you need it. There are additional costs and risks that many non-roll former facilities don’t understand until it’s too late. Can your in-house forming capabilities effectively do the job you need? If you’re trying to decide between a roll forming supplier or in-house forming, there are several key factors to consider. Three of the most important are:

- Cost

- Expertise

- Time

Cost

Has your company considered the price of a cold roll forming machine and the custom die to outfit it? Metal roll forming systems are not cheap. A complete roll forming system can range from $200,000 to $2 million. A standard roll forming line includes:

- Materials handling equipment

- Loading crane

- Uncoiling system

- Pre-punch press (if your part has holes, slots, or tabs)

- Accurate feeder/control system

- Flying die cutoff accelerator with controls

- Appropriately sized cutoff press

If you’re planning on purchasing your own roll forming system, you definitely need high volumes to get a decent return on investment (ROI). With the up-front equipment costs, setup costs and salaries for experienced machinists to run all of it, any potential gains from establishing the process in-house are effectively quashed. Partnering with a roll former saves money.

Expertise

Speaking of experienced machinists, the quality of your parts will depend on the quality of your craftsmen. Their expertise is needed for maintaining a smooth process and troubleshooting when things go awry. The punctual, quality delivery of your parts will be on the line. If your crew lacks the knowledge or skill required for manufacturing the tooling, they may end up with subpar results that could lead to costly errors. Training is essential – and expensive. On the other hand, an experienced roll forming manufacturer has a shop full of roll forming experts. They’re guaranteed to understand and account for variables such as:

- Inconsistent commercial metal thickness

- How to account for part stretching

- How to avoid metal crashing into dies

Time

Time is money – and where you spend it can be a major factor. In-house forming could slow your entire business down, eating up crucial resources to make monotonous, repeating, high volume components. Are those processes keeping up with the velocity of invoicing completed units that you would like? Let a contracted provider that specializes in components support your employees who should be making what you sell … and at the fastest rate possible. Saving time is saving money.

HOW ROLL FORMING LIMITS YOUR TOTAL MANUFACTURING COST OF OWNERSHIP

When it comes to metal forming cost, if price is the battle, total manufacturing cost of ownership – or TCO – is the war. TCO is an analysis of the complete life cycle of your purchase. The number includes every phase of ownership. Parts with a lower TCO are better in the long run when it comes to roll forming cost – even if the initial purchase price is higher. By working with a company that optimizes every step of the roll forming process, you cut costs in ways that aren’t directly related to the per-part cost. So, what are the major contributors to the indirect cost savings of a comprehensive supply planning system?

- Equipment and material costs

- Personnel costs

- Operating costs

- Shipping/transport costs

These factors all play into long-term maintenance and investment in quality. The right manufacturer can help you lower your total manufacturing cost of ownership.

Equipment and Material Costs

These include the cost of equipment, installation, and necessary upgrades. Not surprisingly, materials make up the bulk of roll forming costs. Raw materials can be anywhere from 40% to 80% of the final cost. The cost of a material depends on its thickness, market cost, and scrap factor. A thin, inexpensive material (like thin carbon steel) can take up 40% to 50% of the cost. If the material is heavy and expensive (i.e. copper, bronze, stainless steel), it reaches up to 80% of the total price. The great thing about roll forming is that it produces little scrap – on average, only 0.5% to 3% scrap is produced. So, there won’t be as much monetary or material waste once you buy the materials.

Personnel Costs

These include in-house staff and any outsourced help. Ongoing employee training, project management, and resources for rejects/rework also factor in. The right roll forming partner for you will employ:

- Agile operating practices

- Continuous process flow

- “Pit crew” machine setup philosophy

- Intensive employee cross-training

These practices contribute to a competitive sell price and lower your TCO.

Operating Costs

These include inventory, utility costs, waste disposal, and more. Roll forming is the most economical production process for the bending of metal channels, angles, and complex shapes – remember, there’s very little scrap compared to other manufacturing methods. Also, roll forming produces a lot of metal roll formed profiles in a short amount of time, increasing ROI and decreasing TOC.

Shipping/Transport Costs

If your product requires secondary operations or minor assembly, some roll forming partners will add them to the end of the roll forming line. Doing this instead of adding a separate line or shipping your parts to another manufacturer saves you money. They’ll also work with your current manufacturing shipping companies or use their own to get you the best freight rate.

Grab Your Digital Version of This Guide:

3 FACTORS THAT AFFECT ROLL FORMING COSTS

While roll forming is one of the most efficient and cost-effective methods of shaping metals, there are major factors that affect the cost:

- Setup time – the amount of time it takes to insert and remove the roll tools from the machine.

- Run speed – the speed at which you can feed metal through the machine.

- Materials – the raw materials needed for the project.

Setup Time

This time will vary based on the complexity of the shapes you’re producing, which relates directly to the number of steps required for tool assembly.

Multiple components within a roll form machine affect setup time:

- Pre-punch die design – whether you’re doing multiple small punches or using a large die to do a lot of work in one hit.

- Product shape definition – the complexity of a shape influences the number of roll stations and die spacers needed to form it.

- Cut-off die design – a pure “shear” cut-off, a slug cut-off that produces a scrap “slug” between parts, or a combination cut-off and punching die all have different setup times.

To minimize setup time, the best roll formers deploy “pit crews,” like in NASCAR, to assemble and disassemble each machine. They also use a consistent assembly technique and keep their facilities strictly organized.

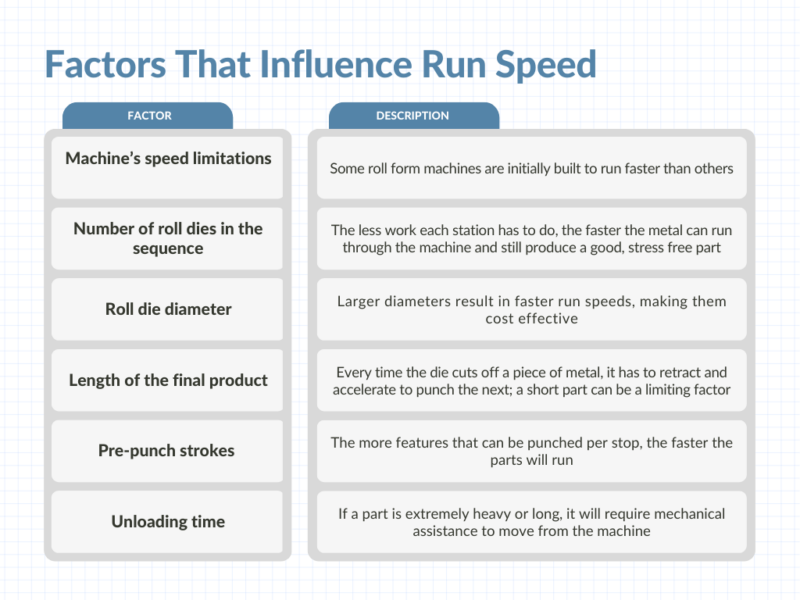

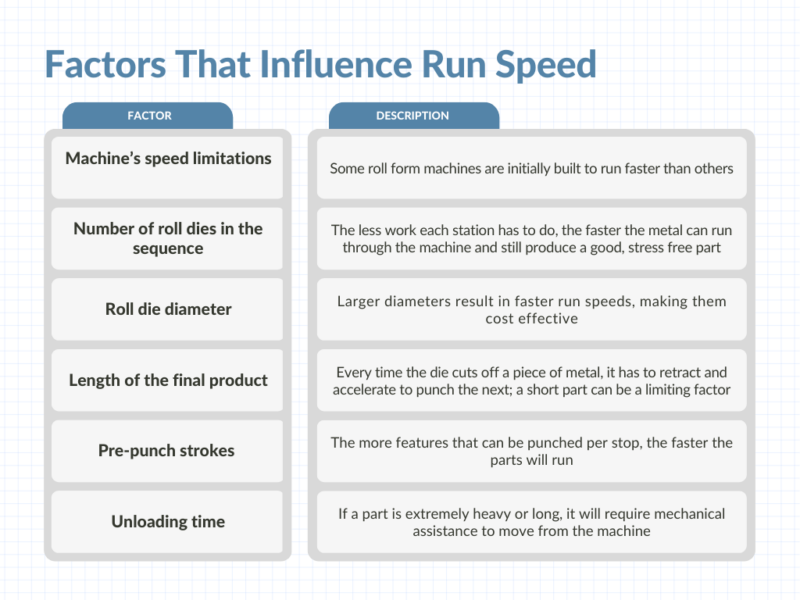

Run Speed

Once you have the roll dies in place and the steel loaded up, a roll form machine will run at a consistent, rapid pace. The faster it runs, the cheaper the components.

Materials

Materials make up the bulk of roll forming costs. As we noted already, raw materials can be anywhere from 40-80% of the final cost.

Popular metals in roll formed products include:

- Carbon/Alloyed Steel – A thin, inexpensive carbon steel can take up just 40-50% of your part cost.

- Stainless Steel – More expensive than carbon steel and aluminum, stainless reaches up to 80% of your total price. Unfortunately, the extra power your vendor must use to form stainless steel increases your labor costs.

- Aluminum – depending on the grade, highly cost effective.

- Copper, Brass, Bronze – Often called “luxury metals,” so they’re quite expensive.

If you’re trying to decide which metal will be the best for your roll formed product, there are several traits aside from cost to consider, including strength and formability. A custom roll forming corporation will help guide you through the process.

Grab Your Digital Version of This Guide:

How to Cut Roll Forming Costs with Efficiency

While the process itself is highly efficient, there’s always room for improvement. Working with a supplier who knows how to maximize efficiency while maintaining quality can significantly cut your costs. If you’re looking at roll forming vs. stamping, press braking, or extrusions on a case-by-case basis for your projects, first determine your order size. Roll form tooling costs may be prohibitive if your annual volume is below 10,000 linear ft. per year – but you could say the same about casting and stamping. At a multi-step job shop, your manufacturer has to:

- Cut the work piece to-size

- Move it to a stamping press or laser cutter

- Move it to a brake press, set the tools, and bend your part into shape

All these steps increase the opportunity to produce considerable scrap waste. This is NOT the case with roll forming… where the scrap rate is only 1-3% of the raw material allocation. Use these tried-and-true roll forming design guidelines to bring down expenses:

Tolerances

Remember, the #1 rule of tolerances for affordability and efficiency is to make them as loose as you can without sacrificing quality and functionality. Avoid tight corners less than 1.5x the material thickness. These cause tools to wear down and break at a higher rate, and could even burn out a low-horsepower roll forming machine. Tight corners can also cause stress cracking in harder roll forming materials.

Complexity of Shape

The complexity of the profile and amount of punching required decides how many tools you will need to complete your parts. They also determine how fast your component can be produced. Profile height may also add to tooling costs, as taller profiles need roll dies with larger diameters. More, and larger, tools will of course cost you more money. The simpler your part’s profile, the fewer tools and less time it takes to run.

Features

Since roll forming is usually chosen during a part’s design phase, you’ll gain some efficiency back by adding several easily repeatable features in-line. While your part is on a roll forming production line, you can incorporate value-added features that may help with mating components.

Material

A thin, inexpensive material (like thin carbon steel) can take up 40-50% of your total cost. A heavy and/or expensive material (i.e. copper, bronze, stainless steel) can account for up to 80% of your total cost. Your roll former can help you decide which material is going to be best for your projects, getting you the results you’re looking for without overspending. Using common metals that are easy to obtain is a good start to conserving material cost.

How to Reduce Raw Material Cost? Ask Your Roll Forming Company

When it comes to cost effectively managing raw materials, wouldn’t you rather work with a custom roll forming corporation that discloses the facts about the largest cost component of your parts?

To recap, the three factors that affect roll forming costs:

- Setup time

- Run speed

- Materials

Of the three, roll forming raw material costs make up the biggest expense – anywhere from 40-80% of the final manufacturing cost.

What is the Biggest Factor in Raw Material Costs?

For a lot of industries that buy formed metal products, pricing is a bit of a mystery. These four variables are sometimes responsible for misunderstandings with buyers:

- True rolled-up cost of raw materials (mill price + servicing cost + freight + etc.

- How much metal is contained per linear foot of finished product?

- How much the metal thickness varies and how that affects you?

- How much scrap figures into the final price?

Unfortunately, failure to understand how to calculate raw material costs creates an opportunity for manufacturers to make money off you.

Instead, roll forming companies should divulge raw material prices openly and honestly. If any you work with don’t or are very hesitant to, that’s a big red flag.

The share of part cost that raw material contributes depends on:

- The amount of metal in the part

- The type & thickness of the raw material

- How much scrap is produced in the process

- Metal market conditions

Falling Prices Slow to be Passed Along

The raw material market changes all the time in metal manufacturing.

When the cost of materials is high, that gets passed on to consumers. When the cost goes down, however, a lot of suppliers are slow to pass along the savings.

Instead of staying true to the market, there may be several pennies skimmed off the top.

Our Raw Material Philosophy

Once you have a complete understanding of a sheet steel supply chain, why should your vendor try to hide anything? Your roll forming company should be performing raw material cost analyses on a regular basis and sharing that information with you.

Roll forming companies should practice transparency with customers by offering a structured quarterly review process as part of their standard roll forming service package. This includes:

- Current market trends

- Consumption rates and inventory levels

- Bids for material to cover the next production period

- Steel mill lead times

After many years of practicing these reviews, you and your roll forming company will know each other very well, and you’ll have a custom solution to keep your roll forming raw material costs down.

The Case For Vendor-Managed Inventory

Vendor-managed inventory is ideal for customers with repetitive, ongoing production requirements. Each system is tailored by product demand but is fundamentally based upon just-in-time delivery and pull system concepts.

If an OEM holds inventory that collects dust for too long, it can negatively affect the company’s bottom line or force it to ship unwanted products to its clients. Vendor managed inventories (VMI) are great in preventing this from happening. Benefits include:

- Lower inventory investment

- Reduced administrative costs

- Better logistics management

Lower Inventory Investment

You provide your supplier trigger information directly from the point of use, while your supplier responds via a robust replenishment system.

Once a replenishment signal triggers, your stock is automatically refilled to a predetermined level. As a result, you avoid stocking up needlessly.

Reduced Administrative Costs

Automating triggers with your supplier reduces the time an administrator spends monitoring your inventory. VMI reduces time (and money) spent managing orders and delivery dates.

Better Logistics Management

As you increase the number of suppliers involved in your project, you create a complex chain of communication. This can cause significant stress on your procurement and logistics teams.

Subscribing to a single-source model of roll forming production:

- Simplifies communication

- Eases the quality assurance process

- Lowers transaction costs

- Lessens lead times

Beyond Costs: Roll Forming Advantages & Values

Working with a company that optimizes every step of the roll-forming method, you cut costs in ways that aren’t directly related to the per-part cost. So, what are the total cost savings created by a comprehensive supply system and the inherent roll forming advantages?

Many of the perks of cold roll forming aren’t found in other metal forming processes.

The true value of metal roll forming comes from:

- Inventory management

- Quarterly reviews

- Quality systems

- Safety

- Cross-trained workforce

1. Inventory Management

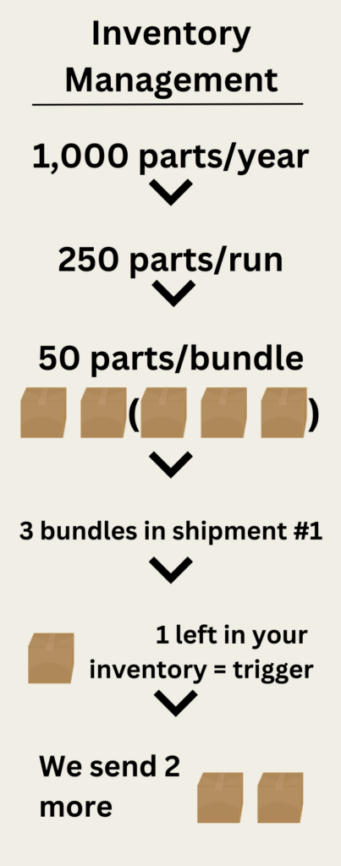

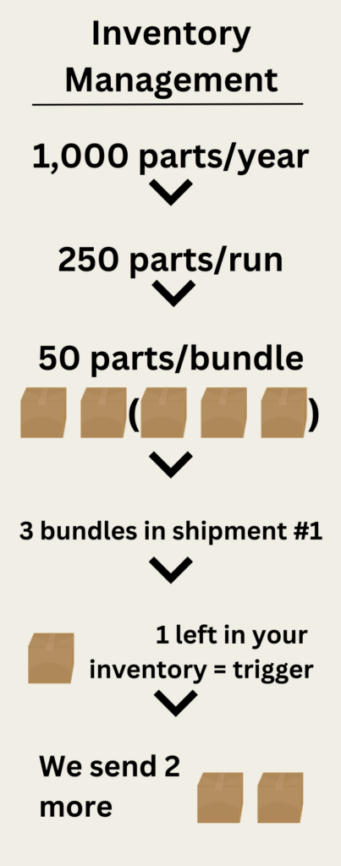

We’ve found that the most cost-effective style of inventory management is one of Kanban-based trigger-response.

Kanban and the just-in-time (JIT) system go hand-in-hand. The Kanban method of inventory control aims to provide the right amount of inventory in the right place at the right time. It requires in-depth analysis to understand how much inventory to hold at a given time, when to replenish inventory, and how much to replenish.

In sum, you give us the trigger information directly from your point of use (ideally from the people using the parts), and we respond based on our replenishment system design.

This management style works for both raw materials on our roll-forming production line as well as your finished product inventories.

Product Inventories

The cycle starts with an estimation of yearly consumption (which gets more precise and seasonal the longer we manage your orders) divided by an economic order run quantity. That helps your company figure out how many “bundles” should be in your system. Then, we ship and track amounts of those bundles depending on your trigger points.

For instance:

You consume 1,000 roll-formed products a year, and we run the pieces four times per year – so, each run produces 250 pieces. We organize the pieces into bundles of 50 pieces each, which means there are always five bundles in the system.

We ship you three bundles to start. (Shipping only a portion of the product at a time helps you keep inventory at a minimum, and assists us in our tracking and distribution of the product.)

Every week, we will get a simple report from the department using the parts that shows how many unopened bundles you have left in your inventory.

For the first two weeks or so, that number is 2. As soon as you indicate you have only one unopened bundle left, that’s our trigger. We immediately release two more bundles so you have three again.

If for some reason you indicate that your inventory is dwindling more quickly than usual, or you’re not using as much as expected, we can adjust our output to meet your needs.

We’ve found the trigger-response system is as close to foolproof as you can get for roll-forming applications.

Problems With Other Systems

Other systems, like enterprise resource planning (ERP), computer systems, and barcodes, are all viable – however, we’ve found there’s too much room for human error or system failures.

With an ERP system, you might have a note that says you will use no more than three pieces of material for each unit manufactured. This sounds perfect in theory, but human error quickly gets in the way. People drop, scratch, and otherwise damage items all the time – and those instances often go unreported due to forgetfulness or fear of repercussions. So, more inventory is being used up without any documentation.

In these situations, it’s very common for the manufacturer’s personnel to go to a shelf in search of an item, only to find the inventory has been emptied. This misunderstanding of true consumption is an unnecessary waste of time and reliability for suppliers and customers alike.

It doesn’t matter if personnel use a little more (or less) than expected, with the trigger-response system. The only thing that matters for the consumption-replenishment cycle is how many unopened bundles are left on the shelf.

Raw Material Inventories

On our end, we use the same system of triggers and responses to make sure our coil inventories are correct. Wide master coils are slit into smaller run coils; when we hit the run coil trigger at our steel supplier’s warehouse, we order another master.

This system allows us to be more flexible when buying materials for clients. We don’t hoard inventory, so we can quickly change gears if a client no longer needs a certain product. We can stay close to market pricing as well, rather than gambling with your raw material dollars.

2. Quarterly Reviews

To make sure you’re getting the most out of our supply planning system, we sit down with you and discuss the results. Quarterly reviews are frequent enough to catch issues as they crop up, and make small changes for the next review.

In particular, we like to make sure the inventory levels are spot on. We track all feedback from clients and after one year, we can optimize for your activity levels in each quarter.

Also, we like to collaborate with our clients to plan the next materials purchase. We discuss:

- How much we have in our inventory

- How much you need

- What the market looks like for your material

- Changes in estimated annual volume

- Pending design changes for your roll-formed parts

- Freight utilization

- Cost-saving ideas

Because we work directly with you, you’ll get exactly what you need for your specific roll forming process.

3. Quality Systems

Dahlstrom Roll Form is ISO 9001:2015 certified, uninterrupted since 1995. This certification indicates that our quality management system meets the International Organization for Standards’ global requirements.

Proofs of the quality system include:

- On-time delivery percentage (99.5% in 2021)

- Field defect parts per million (3,827 in 2021 – four sigma level is 6,210)

Our customers enjoy the confidence that comes from quick delivery times and a low PPM defect rate.

4. Safety

Aside from being ISO certified for quality management, we’re also SHARP (Safety and Health Acknowledgement and Recognition Program) certified for our safety practices. This certification is the highest recognition given by OSHA for exemplary safety practices.

By promoting safety for our employees, we also promote safety for our customers. Some of our safety precautions include:

- Weekly housekeeping & organization audits: Removing clutter and potential hazards from the workspace

- Monthly safety training: Bringing in a safety consultant to talk to the whole staff about general safety practices (lifting heavy things, hazardous chemicals, personal protective equipment, etc.)

We are audited by the Department of Labor regularly to maintain our SHARP certification.

5. Cross-Trained Workforce

Our personnel has a vested interest in the success of your product. All of our operators are paid by the acquisition of skill rather than tenure. The faster they learn and the better their skills, the more they get paid. They have every reason to put out the best quality parts for you.

This program includes cross-training for different roll forming machines and client jobs. If something were to happen to the primary employee who runs your product, there’s guaranteed to be another person who understands your tooling costs and part quality requirements.

That means your project will be on time, and you’ll have no unexpected delays on the roll form line or increased costs for idle time.

Benefits of A Comprehensive System

When you go with roll forming services that include all of these systems, you get:

- Reduced waste & optimized materials costs

- Involvement & complete transparency in the buying process and other processes

- Confidence in on-time delivery and part quality

- No wasted or idle manufacturing time

Not all of these translate directly into monetary savings, but they can be just as valuable. The knowledge that your metal forming partner is working to optimize all of your parts and processes is incredibly important.

Cost Savings & More with Your Custom Roll Former

Dahlstrom Roll Form is more than an OEM manufacturing company; we’re a solutions partner. We combine roll form engineering expertise and lean factory processes to ensure we manufacture your product to your specifications. We strive to understand your business needs as well as you do. All while helping you save on your roll forming costs.

Book a meeting with us to discuss your roll forming needs.