The world is full of long and slender metal components, from warehouses and data storage to commercial refrigeration and HVAC systems. Industries worldwide trust roll formers to produce these components efficiently and cost-effectively.

Dahlstrom has manufactured high-quality, roll formed parts for nearly 120 years. Our parts have been used in solar panel racking systems, commercial warehouses, and even adorn buildings like the Empire State Building.

We go to great lengths to understand our clients’ businesses and their needs and partner with them to create quality, custom roll formed parts.

WHAT DOES A ROLL FORMER DO?

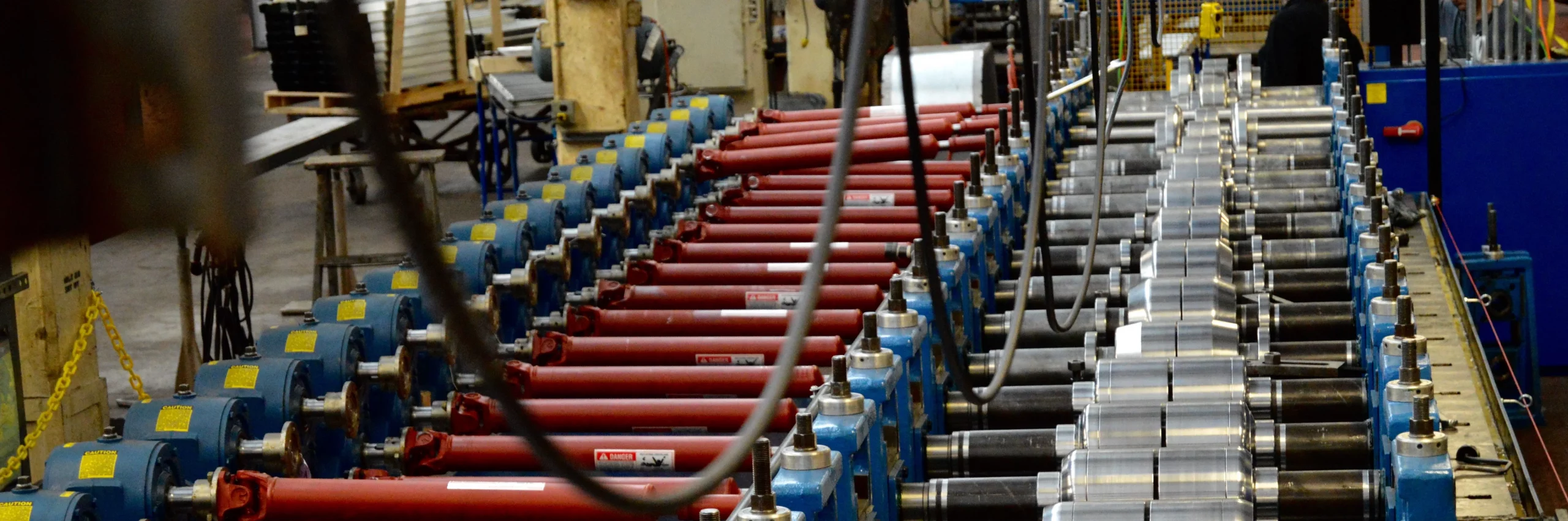

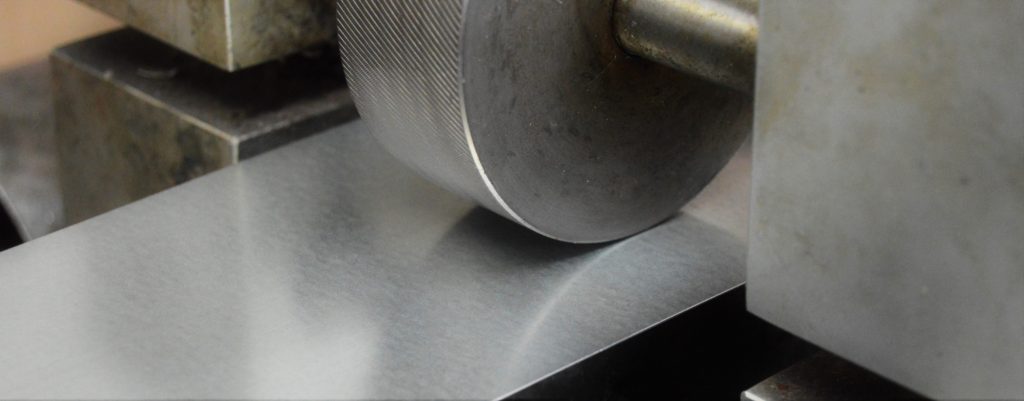

So, what is roll forming, exactly? This process involves heavy machinery that gradually bends flat sheet metal into a long uniform profile by passing the sheet through a series of mated roll dies.

While there are many ways to manufacture metal components, roll forming is the most economical process for the mass production of:

- Angles

- Channels (U, C, J, box, hat)

- Parts with complex, cross-sectional shapes

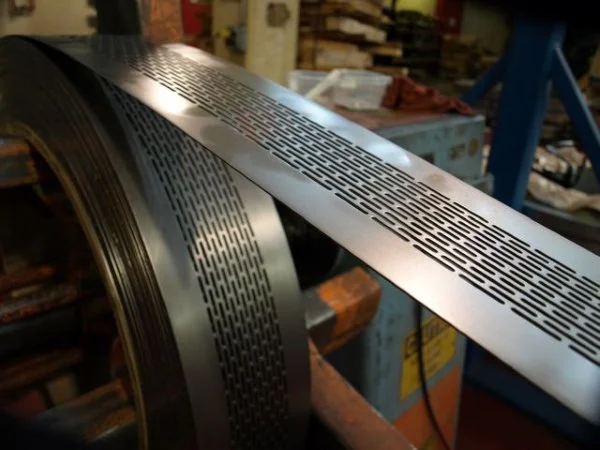

- Parts with intricate hole patterns

- Parts with continuous length of 20+ feet

Roll forming also promotes the free addition of in-line punching features like:

- Holes

- Notches

- Slots

- Embossments

Designing these elements into your custom tools eliminates slow and expensive secondary operations. In doing so, roll forming lowers production costs and significantly slashes lead times.

Benefits of Working With a Roll Former

Original equipment manufacturers (OEMs) and architectural designers rely on Dahlstrom Roll Form because of:

Original equipment manufacturers (OEMs) and architectural designers rely on Dahlstrom Roll Form because of:

- In-line features

- Order volume flexibility

- Complex profiles with intricate bending

- Tight, repeatable tolerances

- Large material size

- Little tool maintenance

- The ability to form high-strength metals

- Tooling ownership

- Less human error

- Less scrap

In-Line Features

Roll forming allows for advanced in-line addition of punched features and embossings. We eliminate multiple-stage operations, excessive scrap, and slitting burrs.

Order Volume Flexibility

Although high volume is the most cost-effective way to utilize roll forming, small and medium runs don’t have to be a non-starter. Depending on your part design, volumes as low as 10,000 to 20,000 linear feet per year can be cost-effective.

Dahlstrom Roll Form can also provide economic order quantity runs. These allow for inventory to be held by us and distributed to you when needed. Economic runs maximize volume and reduce setup time, ensuring you don’t run dry.

We also discount small orders in exchange for a longer-term contract.

Complex Profiles With Intricate Bending

Roll forming allows us to go where many other metal forming processes don’t dare. With clever engineering, we can produce a wide range of cross-sections cut to the length you need.

Designs with multiple bend radii cause problems in press brake forming for several reasons. The same goes for multiple-angle parts – alternative processes create production delays by requiring frequent tool changes and equipment resets.

Tight, Repeatable Tolerances

We turn out high-precision parts.

Roll forming can hold tolerances up to +/- 0.005” on some profile segments. Overall part lengths can be accurate up to +/- 0.020.”

Designs should take end flare and springback into consideration. We understand how to control these distortions with proper design and roll forming production setup.

Little Tool Maintenance

Tool maintenance tends to be less for a roll formed section than for a stamped component because we produce parts and features in a continuous motion.

The best way to determine the scope of tool maintenance is to look at your order volume.

Capable of Forming High-Strength Metals

Not all metal manufacturing processes can handle high-strength metal. Or, if they can, it’s at the cost of rapid tool damage.

Dahlstrom Roll Form can form high-strength materials such as high-strength, low-alloy (HSLA) steel, giving you an advantage over standard-strength materials such as 1040 carbon steel. HSLA steel is a good choice for structural components in various industries, including automotive and construction.

Ownership of Tooling

Cost amortization allows you to maintain full ownership of your tooling and avoid hidden fees. You also get:

- Lower total cost of ownership: Amortization immediately reduces up-front manufacturing costs and enables you to make small payments.

- Long-term ROI: You pay once for the tools and can keep them for other projects!

- Flexibility: Want to take your tooling elsewhere? You paid for it. It’s yours to take.

Fewer Chances for Error

Roll forming equipment in the 21st century is beautifully efficient. Thanks to CAD software, the machines are highly automated, requiring less labor. That means fewer chances for human error.

Speed and adaptability are necessary for industries with quick turnaround times.

Less Scrap

Roll forming produces less scrap waste than other metal forming methods.

Scrap cost is typically 1-3% of your overall cost. This perk is especially significant when you’re working with expensive materials.

Should Your Company Partner With a Roll Former?

Roll forming allows us to produce basic profiles and profiles that are more complex than other metal forming techniques can handle.

Working with a roll former is the right choice if your project has:

- Long, slender shapes (up to 30’ long is common)

- Repeating punch patterns in a family of varied length parts all sharing the same profile

- Medium to large annual volumes (tooling can get expensive for short runs)

- Aesthetic projects where tool marks aren’t acceptable (the gradual shaping process eliminates tool marks!)

- Complex cross-sections profiles

- Deep U-shaped channels with narrow openings

Specific Roll Forming Applications

Roll forming is ideal for many industries – some obvious, others not so much. Dahlstrom Roll Form has created parts for several applications, including:

Solar Panel Mounting Components

Solar Panel Mounting Components

Roll formed parts make up the framing system that holds many solar panels on:

- Commercial roofs

- Utility-scale solar power farms

- Residential roofs

American roll formers take solar market projects more than any other type of job.

Construction Framing

Most commercial buildings are built with parts made from a roll forming machine.

They’re put out very quickly by companies dedicated to this super-niche industry and have the required specific certifications. The architect needs to know the part can meet loading standards and requirements before they’ll consider it.

Tubing

Nearly all tubing is roll formed. Tubing is prevalent in manufacturing appliances, automobiles, architecture, and more.

Tubing can be square, round, oval, or rectangular. All tubing is welded seamlessly in roll forming, thanks to scarfing. Pipe roll forming works the same way.

Roll formed tubing comes in many forms of metal. Occasionally, however, aluminum tubing is done by extrusion instead.

Railings

Millions of miles of guard rails have gotten their sturdy, strong shape from roll forming.

Guard rails can be galvanized right at the plant. Adding that zinc layer helps the component stay resilient in all conditions.

Siding & Roofing

The entire building shell can be made with roll formed components.

You’ll see a lot of metal roofing on houses around the Northeast U.S. That’s another commodity business dominated by just a few roll forming companies.

Other Structural Components

These roll formed components require a heavier gauge. Purlins or Z profiles are used for all kinds of heavy-stress structures.

Typical applications for roll formed automotive parts include:

- Steel frame rails

- Bumpers

- Door beams

- Roof bows

HVAC

There’s a ton of roll forming at play here.

All the tubing in a refrigerant exchanger is made of roll formed copper. Plenty of structural components for the outside shell are roll formed.

In commercial food storage, roll forming creates:

- Kick plates

- Stainless steel rails on the edges

Decorative trim and cornice work for appealing displays in grocery and convenience stores.

Windows

You can order window stiles and rails made from roll formed parts. (Stiles are vertical profiles, and rails are horizontal pieces.)

Hollow window trim reduces your costs while giving you an elegant design. Plus, you simply install it by snapping it on!

Door Components

Roll formers can create door frames, casings, and other parts. Many versions of this framing are available for the edges, bottom, and top of your door, depending on what type of hardware you use. Roll forming of these parts is quite common.

Higher volume “standard” doors use roll forming for door edge, top, and bottom framing, which results in lower costs.

You can also use roll formed parts to add glazing. These can be either flush mounted or overlapping.

Finally, some door faces are roll formed, too. If so, the door manufacturer often handles this process rather than a third party.

Elevators

Roll forming is used for elevator shaft tracking and some structural cab components.

Roll formers can also class up an elevator. Interior decorative cab components are also roll formed.

Construction Equipment/Auto

Any kind of transportation is a target for optimization via a switch to roll formed parts.

Structural chassis components are the bulk of the industry. Do you want interior doors that protect a driver during a crash? Use roll formed parts.

The back structural components and the chassis of trailers and trucks are roll formed. The outside shell uses decorative metal trim.

Trains

Trains

On trains, the siding can be made using a roll forming machine. This is common for city public transportation.

Trains also use structural and exterior and interior decorative metal parts made through roll forming.

Ships

There’s untapped potential for decorative metal components in ships (think work and government boats).

Roll formed parts can adorn the stainless steel furniture inside. Roll forming opportunities abound for cabling and power table trays. They can be hung along the length of the ship for convenience and reliability.

Power Distribution

Cable trays and wire raceways are typically made of galvanized steel, which roll formers can handle just fine.

Copper busbars/conductors are commonly roll formed.

Roll Forming Costs

Roll Forming Costs

The cost of roll formed parts is determined by several factors:

- Complexity of shape

- Labor

- Raw material cost

- Tooling

- Order volume

Complexity of Shape

The complexity of the profile and the punching needed will determine if any cost is added here.

Profile height may increase tooling costs. Taller profiles need roll form tools with larger diameters, which adds to the amount of tool steel needed.

Want to learn how to make a great roll formed part?

Download our guide:

Labor

Most of the labor involved in roll forming involves setting up the line. Roll forming is a single-stage process like a pit crew in auto racing, where many workers set everything up at once. After a roll forming line is set up, the process is automated.

Raw Material Cost

Your biggest cost with roll forming is the price of the raw material, coming in between 55-70% of the final price. The beauty of this process is that it produces so little scrap that it only comprises 1-3% of the overall cost.

Tooling Costs

Roll forming tooling costs are not as high as you may think.

First of all, tooling for any kind of metal fabrication can be expensive. With smart purchases, roll form tooling is no more expensive than any other type. Here are a few ways to control tooling costs:

- Dahlstrom participates in part design and can optimize the part for roll forming tooling.

- Payments can be amortized over time to avoid high up-front costs.

- We discount tooling in exchange for a commitment to buy a certain number of parts over time.

- We’ve been around for nearly 120 years and have all kinds of existing tooling we can use for your project.

Order Volume

The cost-competitiveness of roll forming doesn’t depend on order volume as much as you’d think. High-volume orders make sense, but we can optimize our process for smaller orders.

Why Working with a Roll Former Is Not As Expensive as You Think

You may have heard working with a roll former is expensive! The claims often don’t factor in cost benefits, such as:

1. Added Value In-Line

After you buy punch tooling, you effectively get the holes put in the part for free. The shape has to be formed anyway, and the punching process is connected and continuous.

Unlike other metal fabricating, where adding any feature is a recurring and cumulative cost, roll form costs are based on machine run time – no matter how many features you add.

2. Lower Labor Costs

With fewer processes involved, it’s only logical that you also benefit from tremendously lower labor costs. We’re talking 6% of the total project cost, whereas it’s 15-20% at a job shop.

3. Improved Lead Time

Lead time on a per-part basis is superior. We’re talking as little as

10% of that job shop’s lead time.

4. Lower Part Cost

The amount of tooling cost you add is offset by the efficiency of the added features.

Compare that payback to a multistep job shop:

- Cutting the piece

- Taking it to a press or laser cutter

- Taking it to a brake press, where someone sets the tooling and bends your part into shape

We handle all these steps in a continuous process. Roll forming is ideal for repeatable parts and processes.

5. Ability to Collaborate on Optimizing the Part

We offer design assistance, which saves you money by optimizing the part for roll form tooling and processes.

Roll Forming Vs. Competing Processes

In the right situation, roll forming produces parts efficiently that stack up against any industry. Here are the pros and cons of roll forming vs. stamping, press braking, extrusion, casting, and forging.

Most of these competing processes are done through hot forming. The challenge is that hot forming is a very specialized mill process. The use of high temperatures and molten product requires huge furnaces, which aren’t exactly in abundance. Buying the machinery needed to manage molten steel safely is a large expense. So is finding experienced labor to operate the equipment.

And the Difference Is …

There are general differences in the end result of cold forming vs. hot forming:

- Run speed and quality: With hot steel, it might take 50 rolls to thin a workpiece out, while that same piece may require 100 passes with cold roll forming. However, with more rolls, you can get tighter tolerances on the piece and a higher-quality end product. This can increase costs, but it may be worth it to your customer.

- Strength: For similar grades, cold rolled metal can be stronger than hot rolled metal because of work hardening.

- Structural uses: The formula of steel for “I” beams is different than what’s used in cold forming. It’s less ductile and harder, making it tougher to bend while cold.

- Size limits: Steel sheet is only hot rolled up to a certain thickness. Roll formed parts are limited in length only by the amount of material in the coil.

Roll Forming Vs. Stamping

Stamping is not ideal for low-volume projects, partially because the tooling cost of stamping is large. Stamping can’t form long parts, and changes to the punching pattern can’t be made.

There are certain high-volume, simple-design applications that can be stamped. These include:

Gears

Gears- Engines

- Aircraft components

- Electronics

- Telecommunications

- Hardware

- Power tools

- Appliances

- Lock hardware

- Lawn care

- Ammunitions

- Lighting

Roll Forming Vs. Press Braking

Press braking suffers from some of the same deficiencies as stamping does, and then some. It’s also ill-suited for longer components as well as complex bends, angles, and radii.

In general, press braking gives you inconsistent results. You never know when you’ll end up with scratches and other tool marks. Press breaking is much better for low-volume orders than high-volume ones.

Applications for press braking include sheet metal components.

Roll Forming Vs. Extrusion

Extruding is more competitive with roll forming than the first two processes.

For a high-volume run, extrusion equipment and tooling can be expensive. Everything requires secondary processing, and there are no value-added activities that can be done in-line.

Extruding is yet another process constrained by component size limits. This process isn’t great for long or thin parts.

Still, there is no shortage of applications where extrusions are preferable to roll formed components – especially when working with aluminum. Structural shapes are often made with hot rolling (a combination of extrusion and rolling) to achieve a good weight/strength balance.

Besides structural components, applications for extrusions include:

- Tubing

- Aluminum cans

- Cylinders

- Fuel supply lines

- Frames

- Tracks

- Rails

- Rods

- Bars

- Fittings

- Injection tech

- Electrodes

Roll Forming Vs. Casting

Casting mostly competes with powder metallurgy, but there are a few occasions when it competes with roll forming.

From an efficiency standpoint, casting isn’t good for high-volume batches. From a quality standpoint, it produces parts with high porosity, which depending on your application, could be a no-go.

Here are the applications where casting does become viable:

- Prototyping

- Heavy equipment

- Appliances

- Motors

- Artillery

- Art

- Casings & covers

- Diffusers

- Valves

- Camera bodies

- Wheels

- Tooling

Roll Forming Vs. Forging

The heat involved in forging results in extremely hard components. Sometimes this is a good thing; other times it’s a recipe for failure. High hardness is great for parts that need to resist denting and scratching. But with hardness comes brittleness – high-hardness components have low impact resistance, making them a danger for some transportation projects.

Forging is used for:

Forging is used for:

- Gears

- Steering arms

- Shafts

- Flanges

- Valves

- Drill bits

- Sockets

- Hooks

- Ball joints

- Missiles

- Kingpins

- Axle beams

- Landing gear

- Couplings

Doing It In-House Vs. Partnering With a Roll Former

After weighing the options and deciding roll forming is right for your project, another decision needs to be made: doing it yourself vs. using a contract roll former.

Bringing roll forming processes into your business is a complicated investment. It’s more than buying a sheet metal roll forming machine you can turn on and off as needed. There are additional costs and risks that many facilities that don’t specialize in roll forming fail to understand – until it’s too late.

That’s not to say you can’t do it. Your level of success just depends on your specific operations, needs, and goals.

Your three options are:

- Buying a roll form machine online

- Having a new-equipment manufacturer design and install a turnkey custom roll forming machine

- Outsourcing to an experienced roll former

Three factors should influence which path you take:

- Cost of equipment vs. ROI

- Operator skill vs. quality control

- In-house inventory management vs. vendor delivery

1. Cost of Equipment Vs. ROI

Roll forming equipment is more than just the forming machine itself. A full line includes:

- Material handling equipment

- Loading crane

- Uncoiling system

- Pre-punch press (if your component has holes, slots, or tabs)

- Accurate feeder/control system

- Flying roll forming machine die cutoff accelerator with controls

- Appropriately sized cut-off press

All of these features of the line must match your forming tools, pre-punch die, and cutoff die.

The cost of a complete roll forming system can range from $200,000 to $2 million, depending on the complexity of your component family. Most in-house systems can only produce a single-part profile. A typical line can produce about 1.5 million linear feet per year in a single-shift operation.

If you’re planning on purchasing your own roll form system, you must produce high volumes to achieve decent ROI.

2. Operator Skill Vs. Quality Control

Unlike press brake machinery, roll forming lines require operators with years of experience to ensure high-quality outputs. Here are only a few of the considerations for each line:

- The thicknesses and properties of commercial metals vary greatly

- Runs with various lots of metal require precise adjustments to produce the expected profile

- Adjustments must be made to account for springback of harder metals

- Thicker lots require more space between roll forming tools

- Unequal pressure on roll forming shafts will cause twisting and bowing

- Accounting for component stretching

- Avoiding metal crashing into roll forming machine dies

Can your in-house operators cover all of these bases and provide superior roll forming jobs? If not, you may want to consider outsourcing.

Dahlstrom Roll Form understands and accounts for these variables. Seasoned operators can run multiple profiles and metals on a single line.

Experts are expensive to hire full-time for your own operations. And, if you need service contractors, they probably won’t have schedules that meet your urgent needs. That puts your supply chain and your customers at risk.

3. In-House Inventory Management Vs. Vendor Deliveries

Inventory control is a major reason that companies bring roll form projects in-house. But how does inventory control stack up against the cost of in-house roll forming? Ask yourself:

- Will there be a full-time line operator?

- High volumes require full-time teams on the line. Will your company be able to balance the cost, output, and other dependent processes of that workload?

Dahlstrom Roll Form already has balanced systems to provide full-time roll capabilities at a manageable cost.

We can also manage inventory for you – whether that means JIT (just-in-time delivery) or high-stock, as-needed deliveries. Inexperienced inventory management can cause costly supply chain snags.

More on ROI

Trusting a third party can be scary. If you’re weighing whether outsourcing your manufacturing is worth it, remember that outsourcing just one part to a U.S. roll former can improve ROI.

It’s possible to increase your shippable units by 20% to 50%. Here’s how and when that’s possible:

When to Turn to a Roll Former for ROI

Almost all roll formers have equipment and processes designed to provide customized features inherent to the uniqueness of their products. Whether these features contribute to a unique function or offer customers additional options, they form the core differentiation that supports their existence. It makes sense that these specialists’ investment in …

- Equipment

- People

- Processes

- Factory space

… should favor them over keeping processes in-house.

Another consideration: What kinds of orders will you produce? Higher-volume, commodity items could put a death grip on your organization’s ability to increase shippable units. If capacity on the line is constricted by even one higher-volume component, outsourcing this part to a roll former can exponentially increase your profitability.

Profitability is about accelerating the rate of shippable units using the same costs and existing investments. Experienced third-party suppliers are born for that.

So, although in-house roll forming is appropriate for some companies, it’s not a cost-effective alternative for everyone. For many, a contract roll former will produce higher ROI and reduce stress levels.

Partnering with a roll former: The Next Steps

If you’ve decided that you’re best passing off production to an outside roll former, we’d love to talk! We offer a comprehensive supply system. Our supply agreement will result in:

- Cost savings

- Reliability in lead times and the supply chain

- Understanding the framework of your supply system

If you’re not your OEM’s final decision maker, you may encounter a skeptical boss. If your project fits at least a couple of these criteria for using roll forming, they’ll be sold:

- Your order volumes are outgrowing the ROI of your current processes

- Your scrap waste is out of control

- Your current process is inefficient

- You want more control over processes and tooling

- You want to tighten your supply chain with vendor-managed inventory

- You want to take advantage of lean manufacturing processes

- You want a more environmentally friendly product

If you want to understand the process better, or have specific design questions, get in touch with us today. We’ve been at it since 1904, so we can quickly pinpoint which manufacturing process is best for you.

Gears

Gears