A MANUFACTURER’S GUIDE TO PARTNERING WITH A RELIABLE ROLL FORMER

This guide walks you through what to expect when looking to partner with a quality roll former.

We cover (click the text to jump to section):

- What to Expect From Full-Service Roll Forming Companies

- Communication: A Key To Supply Chain Risk Mitigation

- Roll Forming Company Supply Agreements Should Look Like This

- Just In Time Delivery: 1 Step a Roll Forming Manufacturer Must Take

- Vendor-Managed Inventory Benefits Your Bottom Line

- A Look at Kanban Inventory Management in Roll Forming

- Cut Lead Time & Red Tape With Roll Forming Tooling Manufacturers

- How Dahlstrom’s Total Cost of Ownership Limits Metal Forming Costs

- Why Working With An ISO 9001:2015 Certified Roll Forming Matters

- Dahlstrom: Your Custom Roll Forming Partner

Work With the Right Roll Former

Work With the Right Roll Former

Your business depends on an intricate supply chain involving numerous vendors.

One kink in the chain can throw your entire system into disarray. While no one can foresee every potential issue, working with businesses that see you as a partner strengthens your supply chain.

Do the companies you work with intimately know your business and industry? Or do they see your organization as just another customer?

Your customers expect you to produce high-quality products. Working with the right partners helps ensure you give your customers what they expect.

What to Expect From Full-Service Roll Forming Companies

A roll former should be more than just another link in your supply chain. A full-service roll forming company is a collaborative partner that offers:

- Expert advice

- Design optimization

- Cost savings

A roll forming company worth doing business with knows your business and your industry as well as you do. Whether you need custom roll forming services for warehouse shelving, architecture, HVAC systems, or transportation, your supplier should understand these businesses are not all the same. Each niche market has its own needs, problems, and opportunities.

Full-service roll forming includes:

- Setup time reduction

- Informed material buys

- Monitored performance data

- Dynamic inventory management

- Supply system reviews

- Tooling ownership

- Economic runs

Full-Service Roll Forming Companies Are Agile

A full-service roll forming company is agile to adjust to your business and be a sturdy link in your supply chain. Agile roll former manufacturers that anticipate your organization’s needs should offer:

- Flexible order sizes

- Shorter delivery times

- High availability/capacity of forming lines

- Problem-solving

- Quarterly customer reviews

Your components are too important to risk with a supplier who doesn’t understand your business and can’t deliver on the points above. Open communication from the start of the relationship will help you avoid future problems.

Communication: A Key To Supply Chain Risk Mitigation

There are so many things that can go wrong in a manufacturing supply chain. Communicating as partners is necessary for effective supply chain risk mitigation.

A roll forming supplier should meet with you at least quarterly to review how things are going and plan for future production. Quarterly reviews allow you to regularly review supply and demand and plan for your company’s future. Your reviews should include discussion on:

Raw material pipeline and cost reviews

Raw material pipeline and cost reviews- Raw material market influences

- Inventory status

- Actual product consumption vs. forecast

- Process transparency

- Upcoming Design Changes

1. Raw Material Pipeline and Cost Reviews

Vendors need to have raw material stock planned in advance to protect supply. A well-designed risk mitigation plan helps you avoid having more material than you need or not enough material and a long lead time before your supplier receives more.

2. Raw Material Market Influences

In some respects, the raw material market is a living thing. It’s influenced by outside factors and reacts accordingly. Among the most common and most impactful factors include:

- Global supply chains

- Demand

- Availability & shortages

You and your vendor should periodically perform market assessments to ensure you buy materials at the best price.

3. Inventory Status

3. Inventory Status

A reliable roll former provides regular and random inventory reports. It also makes supply or safety stock changes based on your short-term needs.

4. Actual Product Consumption vs. Forecast

Roll formers should be able to develop a consumption forecast that helps them anticipate your needs. A good roll former will prevent you from making purchasing mistakes and may even vet your purchase orders. A vendor should never struggle to meet inconsistent demand but should ensure everyone is on the same page.

5. Process Transparency

A quality roll forming partner will strive to make and ship your parts to your standards. A supply agreement with your manufacturer helps both of you know what the expectations are.

6. Upcoming Design Changes

Do you need to make a change to your part? Do you have a new project in the works? Let your roll former know as soon as possible to give them enough time to plan for material purchasing and part production. Communicating this early on will help you avoid having too much finished inventory or raw materials.

WHAT YOUR ROLL FORMING COMPANY SUPPLY AGREEMENTS SHOULD LOOK LIKE

Any business relationship should have ground rules that both parties agree to follow. A supply agreement sets the terms for how your business and the supplier will work together.

Why Have a Supply Agreement?

Disagreements happen in any relationship. A supply agreement ensures both sides are protected should a problem arise.

The benefits of having a supply agreement include:

- Cost savings: Vendor-managed inventory can save your business money and headaches

- Reliability: A supply agreement formalizes a promise to deliver a product that meets specifications for a set price. It also includes consequences in case either party fails to meet the terms of the contract.

- Knowing the specifications of your supply system: The inventory your vendor keeps stays at a predetermined level unless you jointly change it.

Without an agreement, you may run into:

- Lead time & supply chain issues: Without an agreed-upon timeline, you may not receive your product on time.

Lack of important information: Not knowing costs, logistics, and quality assurance can significantly affect your business.

Lack of important information: Not knowing costs, logistics, and quality assurance can significantly affect your business.- Lack of protection: A lack of agreement on details like tooling ownership, freight terms, or what to do with raw materials or finished components in the case of a design change can be costly to both parties.

What Should Go Into An Agreement?

Certain elements are musts for a supply contract. An agreement with a roll forming company should include:

- An escape clause

- Specific component volume

- Contract length

- Promises and protections

- Limits (inventory, damage and remedies, tooling)

- Freight terms

- Tooling terms and agreements

- Pricing

- Limits on inventory shipping

Agreements Give You Peace of Mind

Any supply agreement you reach with a roll forming company will have unique details. The best approach is to partner with a long-running roll forming company you trust.

Just In Time Delivery: 1 Step a Roll Forming Manufacturer Must Take

A good working partnership will have your roll former shipping the right amount of components exactly when you need them. At a reputable roll forming company, just in time manufacturing is essential to a system that has one purpose: to make sure the company doesn’t make too many components for a customer or run out of product when it’s in demand.

A good working partnership will have your roll former shipping the right amount of components exactly when you need them. At a reputable roll forming company, just in time manufacturing is essential to a system that has one purpose: to make sure the company doesn’t make too many components for a customer or run out of product when it’s in demand.

What is Just In Time Manufacturing?

The last thing your business needs is 1,000 extra parts to take up your inventory space. You may not need them for a few months, and you could use that space for other materials. What if your part design changes and you never use those extra parts you already purchased? Or, what if you need 1,000 parts and your supplier has run out of the product right when you need it most? Just-in-time (JIT) delivery prevents these worst-case scenarios from happening. JIT manufacturing is part of an overall approach to efficiency that:

- Minimizes inventory

- Reduces costs

- Boosts productivity

- Keeps up with customer demand

How Do JIT & Supply System Management Work Together?

A reputable roll forming partner is always paying attention to your needs. They seek to get you what you need at the right time and at the best price through:

- Team setups: Setup costs are a large part of the total cold roll forming cost. Team setups allow these costs to be significantly cut and offer flexibility on order volume.

- Smaller Runs: Smaller batches more frequently allow for production runs that match needs more closely while keeping the cost per part the same.

Vendor-Managed Inventory Benefits Your Bottom Line

Managing inventory levels is a delicate balance. You want to ensure you have enough inventory on hand to meet your demand but not too much that you have a surplus collecting dust and depreciating in your warehouse.  Vender-managed inventory benefits clients by taking the oversight of stock levels off of their plates. You and your roll former can develop accurate forecasts to avoid holding excess inventory. Vendor-managed inventory benefits include:

Vender-managed inventory benefits clients by taking the oversight of stock levels off of their plates. You and your roll former can develop accurate forecasts to avoid holding excess inventory. Vendor-managed inventory benefits include:

- Less investment in inventory

- Lower administrative costs

- Better management of logistics

- Less opportunity for part damage or corrosion

- Not worrying that stock will become obsolete

Why Roll Forming Should Always Include VMI

Your vendor should tailor each VMI plan to your company’s product demand. Just-in-time (JIT) delivery and pull system concepts should form the foundation of these custom services. JIT delivery revolves around producing parts based on actual client usage instead of predicted demand. In a typical roll forming VMI program, the OEM client provides a product-consumption forecast to the roll forming supplier. The supplier then takes responsibility for maintaining a mutually beneficial inventory level for that item. VMI is a shared-risk program, often referred to as “integrated supply.”

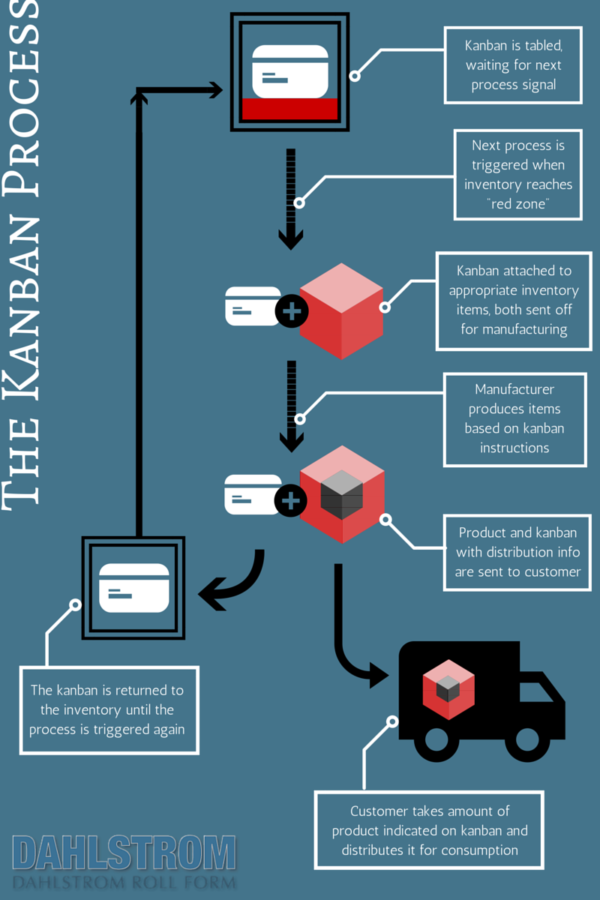

A Look at Kanban Inventory Management in Roll Forming

Kanban inventory management was developed in the 1950s by Taiichi Ohno, an industrial engineer at Toyota. It provides the best control of your supply chain, creating higher inventory turns, fewer inventory costs, and better communication between roll formers and their customers.

Dahlstrom manages inventory for a lot of customers. Before introducing kanban techniques, lead time was slow and the manufacturing process was inefficient. After implementing kanban, we were able to react more quickly to customer needs and manufacture products much more efficiently. Today our on-time delivery date is 99.5%, and our customers love collaborating on forecasting needs.

Dahlstrom manages inventory for a lot of customers. Before introducing kanban techniques, lead time was slow and the manufacturing process was inefficient. After implementing kanban, we were able to react more quickly to customer needs and manufacture products much more efficiently. Today our on-time delivery date is 99.5%, and our customers love collaborating on forecasting needs.

What is Kanban?

The Kanban manufacturing method of inventory control aims to provide the right amount of inventory in the right place at the right time.

There are six kanban principles of inventory control:

- The kanban card indicates how many items the supplier should produce. The supplier creates those items in the amount and sequence specified by the card and ships them to the customer.

- The kanban indicates how many items the customer takes. The customer takes only the number of items specified by the card.

- No items are made or moved without the appropriate kanban attached.

- There should ALWAYS be a kanban with an item; no exceptions.

- Incorrect amounts and items with defects are never sent on to the following process or the customer.

- The fewer kanban used, the more sensitive the process is. Kanban amounts are reduced to decrease inventory and show weaknesses in the system.

Benefits of Kanban Inventory Control in Roll Forming

Kanban inventory management has proved to be a boon to sheet metal roll forming customers. Benefits include:

- Higher inventory turns

- Minimal waste

- Higher quality & quicker response to customer needs

- Lower total cost, since inventory levels are lower

- A stronger relationship between vendor and customer

Cut Lead Time & Red Tape With Roll Forming Tooling Manufacturers

The ideal roll former finds ways to cut lead times and costs while providing the best quality roll forming. Kanban helps manufacturers improve their processes so they can give their customers a high return on their investment.

The ideal roll former finds ways to cut lead times and costs while providing the best quality roll forming. Kanban helps manufacturers improve their processes so they can give their customers a high return on their investment.

Kanban: A Demand-Driven Approach

Kanban is among the most successful versions of a pull production, or “just in time,” approach to manufacturing. When applied, a Kanban system uses a visual approach for task management, complete with cards, bins, or other aids to keep the process in sight and top of mind. The concept is more a philosophy than a system because each application is different with its own challenges to overcome. Centralized tooling storage, an integral facet of Kanban in metal roll forming, seeks to:

- Cuts manufacturing lead times

- Reduces errors by simplifying the tooling identification and acquisition timing process

- Standardizes the manufacturing floor layout

Centralized Tooling Storage Saves Time & Eliminates Costs

The main components of a tool centralization system may include:

- A central tool storage area that serves all production lines

- Moving tools from the central storage area to the roll forming machines via a transfer system with fixed input and output locations.

- A feedback loop indicating when roll forming tooling needs maintenance or sharpening

Benefits of Centralized Storage Practices

The benefits of centralized roll forming tool storage include:- Increased efficiency & productivity through standardization

- Shorter lead times

- Faster setup

- End-customer savings

Centralized Tooling Storage Saves Time & Eliminates Costs

The main components of a tool centralization system may include:

The main components of a tool centralization system may include:

- A central tool storage area that serves all production lines

- Moving tools from the central storage area to the roll forming machines via a transfer system with fixed input and output locations.

- A feedback loop indicating when roll forming tooling needs maintenance or sharpening

Benefits of Centralized Storage Practices

The benefits of centralized roll forming tool storage include:

- Increased efficiency & productivity through standardization

- Shorter lead times

- Faster setup

- End-customer savings

Dahlstrom Roll Form added central tool storage and standardized retrieval systems years ago and found that it increased our response time. It’s all part of the continuous improvement journey toward a shorter supply chain.

How Dahlstrom’s Total Cost of Ownership Limits Metal Forming Costs

Total cost of ownership (TCO) is an analysis of the complete life cycle of your purchase. The figure includes every phase of ownership. Parts with a lower TCO are better in the long run for roll forming cost – even if the initial purchase price is higher.

TCO highlights the difference between the purchase price and long-term cost. It consists of:

- Equipment and material costs: These include the cost of equipment, but also installation, and any necessary upgrades.

- Personnel costs: These include in-house staff and any outsourced help. Ongoing employee training, project management, and resources for rejects/rework also factor in here.

- Operating costs: These include inventory, utility costs, waste disposal, and more.

- Shipping/transport: How efficient is your vendor?

These factors all play into long-term maintenance and investment in quality. That’s where a reliable manufacturer hopefully comes in.

It’s tempting to use offshore manufacturers to produce your components. The initial price looks good but doesn’t represent the whole story. High shipping costs and months-long lead times significantly raise the TCO.

Some businesses are reshoring their manufacturing or using a domestic second-source supplier. Domestic vendors can get much smaller quantities of raw material, produce less waste, and provide much quicker lead times, decreasing your total cost of ownership.

Why Working With An ISO 9001:2015 Certified Roll Forming Matters

Your components are too important to trust with just any manufacturer. Your supplier should be is credible and back up their claims. To that end, An ISO 9001:2015 certification shows the International Organization for Standardization has determined your roll former is a reliable partner.

Being ISO 9001 certified means a business focuses on producing goods and services that meet high-quality standards and conform to regulations.

For manufacturers, including roll formers, ISO 9001 addresses some fundamentals, such as:

- Ongoing improvement in all aspects of the business

- Product and service quality standards

- Appropriate staffing

- Continuous monitoring of products and processes

- Methods for addressing problems as quickly as possible

The certification isn’t the only reason to go with a particular roll forming company. It should, however, be high on the list of qualifiers. A company not organized or proficient enough to keep up with industry standards is probably not a reliable choice.

Dahlstrom: Your Custom Roll Forming Partner

Your company may consider roll forming in-house to save costs and better control your supply chain. However, this may not be the easiest or most economical solution.

Work With A Roll Former Who Cares

Working with Dahlstrom, you get a partner committed to your success, reducing your costs, and manufacturing quality roll formed parts. Here are three reasons to consider partnering with Dahlstrom:

Working with Dahlstrom, you get a partner committed to your success, reducing your costs, and manufacturing quality roll formed parts. Here are three reasons to consider partnering with Dahlstrom:

- We know your business: We work with various companies – each with unique needs.

- We customize for your business: Because your success is our success, we work with you to solve your unique problems.

- We care about your business: We built our success on long-term relationships. As one of the oldest custom roll forming corporations in the U.S., we strive to be a reliable and agile manufacturing partner.

You Could Take Roll Forming In-House, But Should You?

Supply chain disruptions in the past few years have caused problems for almost all industries. Some businesses have considered roll-forming in-house. After all, being able to control parts of your supply chain is less risky than outsourcing. But, this comes with significant cost considerations. Does your company have:- Personnel and space to hold Inventory and keep costs low?

- Processes to minimize stock to reduce costs while providing a buffer for changes in demand?

Choose a Custom Roll Former You Can Trust

Dahlstrom Roll Form is more than an OEM manufacturing company; we’re a solutions partner. We combine roll form engineering expertise and lean factory processes to ensure we manufacture your product to your specifications. We strive to understand your business needs as well as you do.

Book a meeting with us to discuss your roll forming needs.