The forecasts are in: Supply chain woes are here to stay for the foreseeable future.

While disruptions of some sort have always been a part of supply chains, it is safe to say that the COVID-19 pandemic shocked supply chains worldwide. Dependency on overseas manufacturers has led to delayed shipping, increased costs, and production shutdowns domestically.

These disruptions caused many metal roll formers and the businesses that rely on them to rethink their supply chain. Should they decrease their reliance on overseas suppliers and source from domestic suppliers? Is having only one supplier the best supply chain strategy, or should they dual-source? How can they be prepared for the next supply-chain crisis?

These questions come with no easy answers. However, dual sourcing a domestic roll former can help create a more efficient supply chain.

DUAL SOURCING EFFICIENT SUPPLY CHAIN PARTNERS

There is value in having only one supplier. We have even written favorably about this approach; it simplifies logistics and creates a clean vendor-managed inventory program.

But what happens when that valuable partner can’t provide you with what you need? Some experts predict that the COVID-19 crisis will encourage more companies to use dual sourcing to decrease supply chain risk.

Your supply chain strategy should allow you to be prepared, agile, and resilient. Dual sourcing your roll forming needs is an efficient supply chain strategy.

This guide will talk about:

-

What a dual source supplier is

-

Pros and cons of dual sourcing

-

Developing a dual sourcing strategy

-

Why reshoring is important

-

Where agile roll forming fits in

-

How a small precision roll-forming supplier can be a big boost to your business

-

Why just-in-time delivery is important

-

Shipping solutions your roll former should have

What is a Dual Source Supplier?

A dual source supplier is exactly as it sounds: using another supplier for your roll-forming needs. This process involves having a reserve roll former who can pick up your work if your primary source cannot.

Dual sourcing could also look like giving 75% of your work to one roll former and 25% to another. If one roll former experiences trouble, you already know your other partner can produce what you need.

Creating an Efficient Supply Chain: Dual-Sourcing Pros & Cons

Like other efficient supply chain strategies, dual sourcing has pros and cons. However, working with a quality domestic roll-forming company helps mitigate potential issues.

Pros:

- Risk reduction – Relying on a single supplier comes with significant risk. What happens in the case of a disaster? With dual sourcing, you won’t have to scramble to find another supplier should a catastrophe happen to your primary supplier. A second-source supplier reduces the chances of lost revenue from longer-than-anticipated lead times, increased costs of “emergency manufacturing” from a pinch-hitting company, and potential loss of customers.

- Cost savings – We note several potential benefits, including:

- No single vendor can have too much leverage in the purchasing relationship

- Companies compete against each other, meaning you may realize lower supply costs or other benefits

- If you have more than one location, you can choose the vendor closest to your facilities instead of using a single supplier that ships from one place, potentially lowering your freight costs.

- Changing suppliers is simpler – If you need to drop a vendor, the other vendor can pick up the slack while you hunt for a new one.

- Scaling up is smoother – Your growing company may demand more than single sourcing can handle, which means you can’t meet customer demand. A secondary source can take on that added capacity.

Cons:

- Possible quality inconsistencies – Can both suppliers produce the same quality?

- More complicated supply chain planning – You’ll have to manage more than one supplier and any logistical issues that arise. Building and maintaining a good relationship with one supplier is hard enough.

- Pricing volume – Splitting purchases (like that 75/25 example above) decreases purchasing leverage.

Possible added shipping costs – Your primary roll former may be in the same state or region as you. Your secondary supplier may be across the country. The distance is good as having your suppliers close together could mean an emergency event affects both of them and leaves you scrambling for another. However, this could make for some increased transportation costs.

Developing an Efficient Dual Sourcing Strategy

Developing an Efficient Dual Sourcing Strategy

For efficient supply chain management, keep these things in mind when considering dual sourcing your roll forming:

-

Is the supplier reputable? What are their customers saying about them? It may be worth a call to a couple of customers to hear their impressions.

-

How is their customer service? You want a partner that will respond to your needs. They should communicate regularly and let you know if any problems arise.

-

What are their delivery rates? The benchmark for on-time delivery in metal manufacturing is between 70 and 80%. Your partner should exceed this. For reference, Dahlstrom has a 99.5% on-time delivery rate.

-

What is their PPM defect rate? Your partner should ensure your roll-formed shapes arrive on time and meet your quality expectations. For reference, Dahlstrom consistently achieves a field quality defect of fewer than 4,000 parts per million (PPM).

-

Can they produce the volume you need? We’re not just talking large volumes. Depending on your part design, volumes as low as 10,000 to 20,000 linear feet per year can be cost-effective.

-

Can they keep your timeline? – This is where a supply agreement comes in handy. Your roll forming partner should be able to commit to your schedule or let you know if they can’t before the partnership begins.

-

How close are they geographically? We advocate for a domestic roll-forming partner. If you already have one and are looking for another, seek a partner in a different part of the United States. If something goes wrong in your primary roll former’s location, you can rely on your second source supplier to pick up the slack.

As part of your search, ask potential second source suppliers for three quotes (for example, 100%, 70%, and 30% of your business). Doing so allows you to do a cost/benefit analysis to discover how to get the most for your money.

Consider vendors with different traits, like a large corporation and a small local business. They’d have different strengths and weaknesses that could lower your risk in the case of a supply chain crisis.

Reshoring: A Better Dual Sourcing Strategy

There was a time when offshoring manufacturing made financial sense. While international shipping costs are high, cheaper labor and fewer environmental regulations overseas have helped decrease production costs.

Offshoring isn’t as profitable as it used to be and poses more risk than sourcing products at home. Many companies are rethinking the financial benefits of offshoring, leading them to reshore their manufacturing needs.

A survey of 120 manufacturing executives in 2021 found that 41% said they reshored at least some of their manufacturing in the past three years. More than 20 % said they plan to do so in the next three years.

And for good reason. Backups caused by disasters, disruption in significant trade routes, and global pandemics show vulnerabilities in a supply chain. These vulnerabilities increase shipping costs and time, which increase the total cost of ownership (TCO).

When determining if reshoring is right for you, it’s wise to consider:

- Your total cost of ownership

- Adaptability

- Available options

1. Consider the Total Cost of Ownership

Several underlying factors contribute to your total cost of ownership. Before purchasing roll-formed parts offshore, consider:

Lead Time

Shipping parts domestically is faster than shipping parts internationally. When you consider production time of 10-20 days and shipping time of 30-40 days, no overseas manufacturer can meet your needs promptly.

Your supply chain becomes a nightmare of overstock and out of cash or depleted inventory and upset customers. These problems amplify when there are several variations in the part family and “Just in Case” stock explodes, leading to excess storage costs, damage from constant movement, and eventually obsolescence.

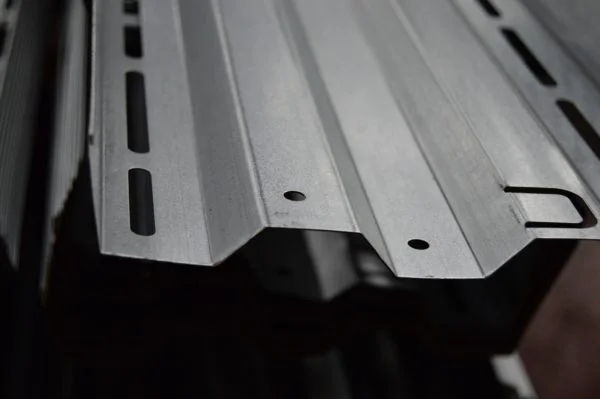

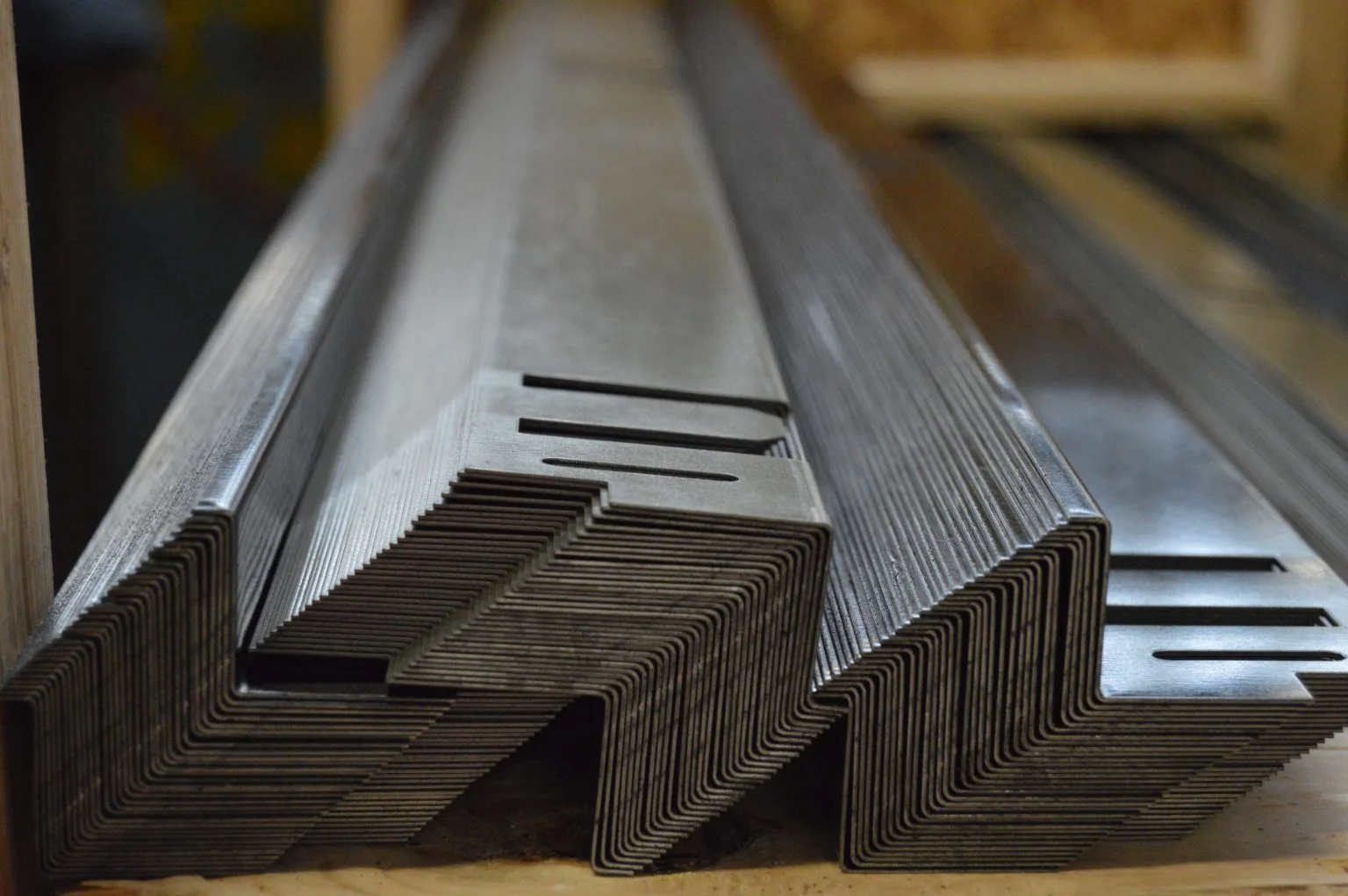

Batch Size

Because the process is so efficient, batch sizes for metal roll forming are almost always big (think 20,000 linear ft. or more). You’ll likely buy more than you need at once to justify the shipping costs. You’ll also want to ensure everything comes together rather than paying for a container after container of smaller orders.

Domestic suppliers can send both small and large orders at any time. Without having to worry about maximizing the container costs, you’re free to order as many parts as necessary without the stress of exponentially adding to your inventory carrying costs. More so, sophisticated domestic suppliers can also “auto-replenish” inventory directly to your point of use.

Material Properties

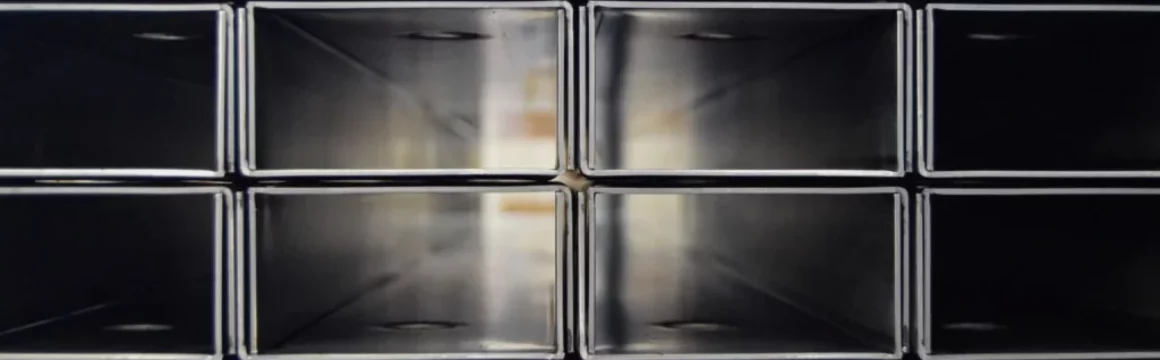

Parts for metal roll forming are typically long and heavy. Most certainly, overseas shipments of metal roll-formed components hit container weight limits before the cubic volume is filled, which means there is a lot of space in those containers that you end up paying for!

Then there’s the corrosion factor. If your part consists of standard steel or a “red metal” that needs to retain its shiny finish, a long trip over the salty sea is… not ideal. Even a few weeks on the ocean can be detrimental to the quality of your shipment, and even more so if terrible weather prolongs the trip.

With shorter lead times, cheaper shipping, and the ability to get you what you need when you need it, it pays to stick with a domestic supplier.

2. Adaptability

Shipping isn’t the only area in which domestic roll formers are adaptable. Other advantages that domestic suppliers have over foreign suppliers include:

- More secure intellectual property – Your intellectual property is in safer hands with American suppliers as the U.S. takes intellectual property rights seriously.

- Various payment methods (including financing) – Foreign manufacturers often require pre-payment and offer a limited number of payment methods. Domestic suppliers often provide many payment and financing options.

- Made in the USA is a selling point – American pride often leads people to find domestic products. Deciding to source parts from within the states can give your company a competitive advantage from a marketing standpoint.

- Time zone differences – The time difference between New York and Los Angeles is easier to navigate than in Houston and Beijing. A domestic roll former can address your needs faster if something goes wrong or changes are needed.

3. Available Options

One of the simplest ways for a company to reshore its supply chain is to talk to a few stateside roll forming companies. They will closely examine your current supply chain and determine if a manufacturer closer to home is the best option for your needs.

Not every roll form company will provide a cheaper manufacturing route than foreign suppliers. A simple remedy is to do your due diligence on domestic vendors.

Is Reshoring Only Part of Your Overall Strategy for an Efficient Supply Chain?

Perhaps reshoring your entire supply chain isn’t feasible. However, having a domestic dual-source supplier will give you added insurance against the risks of using global suppliers. A domestic supplier has more agility to respond to your needs, especially when your international supplier is facing a crisis.

Dual Sourcing Agile Roll Formers

Remaining flexible in a customer-centric way is always the best method. Agility is something that international or large domestic suppliers simply can’t offer. Small-to-mid-sized roll forming suppliers can accommodate your needs.

What can an “agile” roll-former offer? Ask about these six things:

- Flexible order size

- Anticipating your needs

- Shorter delivery times

- High availability/capacity of forming lines

- Problem-solving

- Quarterly customer reviews

1. Flexible Order Size

A large roll former may work with orders between 30,000 to 80,000 linear feet. Or, you may buy more than you need from an international supplier to justify shipping costs.

However, you may only need less than 25,000 linear feet. A second-source supplier may be your best bet if you don’t have the need, budget, or capacity for a high-volume order.

2. Anticipating Your Needs

By studying consumption rates, your supplier can determine what you need ahead of time.

With their evaluation, you won’t receive an order of unnecessary components that waste space and start rusting while in transit.

3. Shorter Delivery Times

Predictive models are a more proactive way for a metal former to protect a customer’s supply chain. By automatically replenishing based on forecasts, a domestic metal former who keeps some stock for you can deliver your goods in as little as 1-3 days.

4. High Availability/Capacity of Forming Lines

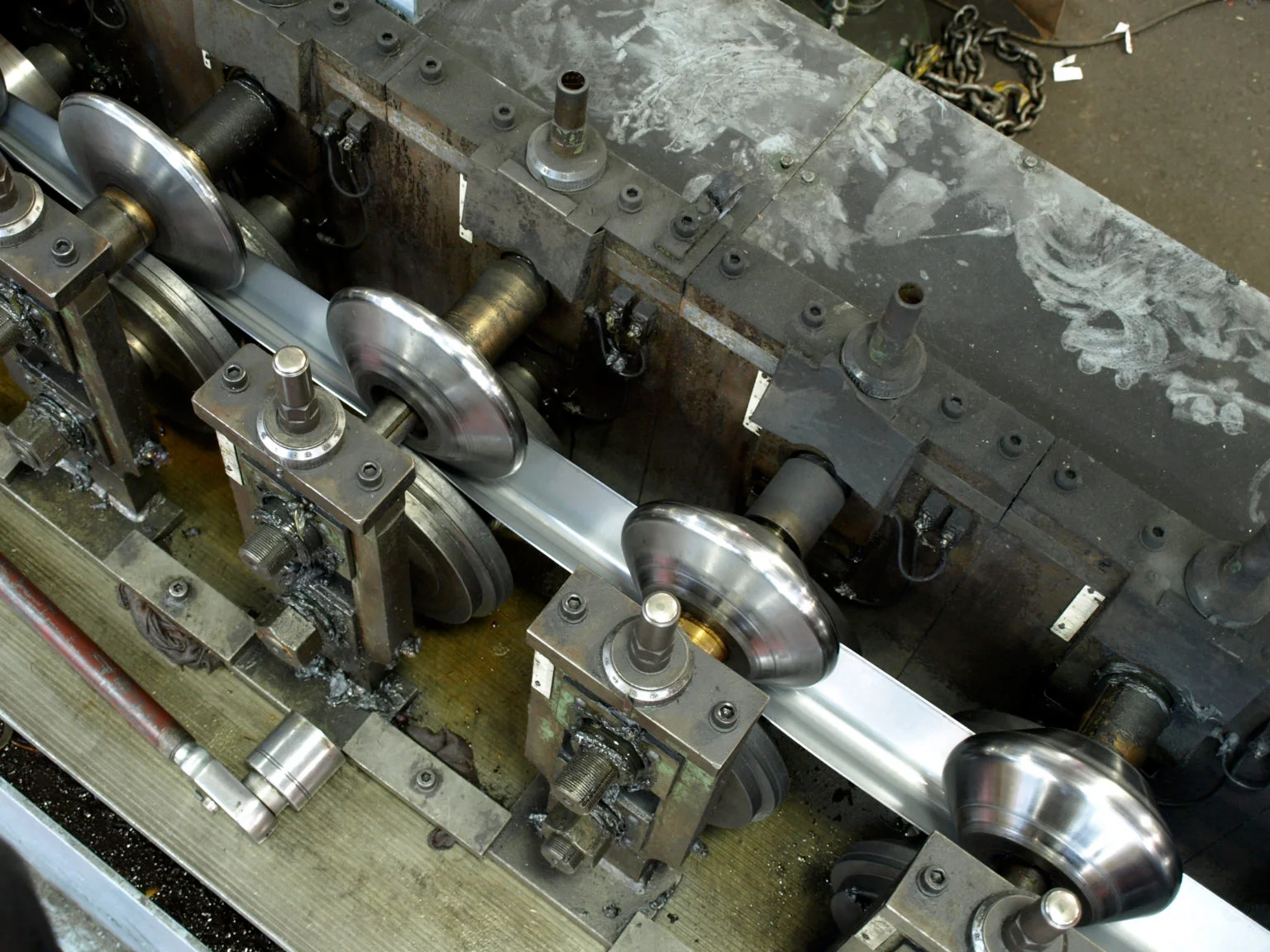

While all roll forming vendors preschedule lines, the smaller companies do it in a more customer-friendly way.

By using “pit-crew” type teams when necessary, agile roll forming companies can break into larger runs to satisfy a customer’s particular need. These companies operate under a simple concept: “If we can cut the setup time in half, we can reduce the batch size by half, and we’re even.” Smaller batches more frequently allow for production runs that match needs more closely.

5. Problem Solving

An agile roll former has a better ability to solve problems as they arise. Maybe production can be streamlined by using a secondary local assembler. Or maybe they can buy a piece of equipment specifically for your job. Perhaps they can perform secondary operations for the convenience of a one-stop shop. Maybe you need to go over potential design changes in parts. An experienced, agile partner can roll with your needs.

6. Quarterly Customer Reviews

Quarterly customer reviews put your voice in front of the supplier’s managers. Your typical large-scale former almost certainly doesn’t do this, and to be honest, not enough small and mid-sized formers do it, either.

Regular check-ins aren’t just about supply and demand — they’re also about understanding your company’s future as well as you do.

A Small to Mid-Sized Precision Roll-Forming Supplier Can Boost Your Business

Your second source supplier doesn’t need to be a giant company. An OEM can get great results from a small or mid-sized roll-form manufacturer. A just-right size allows a roll-formed components manufacturer to focus on doing great work for a handful of OEMs. This strategy is always better than a supplier spreading itself too thin and letting quality suffer.

Benefits of working with a more tight-knit operation include:

- The same standards as bigger manufacturers – Some smaller manufacturers are fully ISO-certified to meet ever-changing quality standards. Many produce shapes using advanced metal roll-forming machinery to meet the demands of some of the most prominent manufacturers in the world.

- Custom, vendor-managed inventory systems – A vendor-managed inventory program can reduce inventory investment, lower administrative costs, free up space in your building, and improve logistics management. A customer-friendly roll-forming company will collaborate with you to build a strategic material purchasing plan.

- A dynamic in-house engineering team – Like any metal manufacturing process, roll-forming design has quirks and pitfalls. Working closely with a small group on the vendor’s side may better educate you on how to optimize your part.

Tools it’s happy to share – Your roll former may already have tooling that will work for your project, keeping you from incurring any up-front tooling costs and overall lowering your roll forming cost.

Just-in-Time Delivery

As we discussed above, having to order more than you need or getting it sooner (or later) than you need it isn’t helpful.

Just-in-time delivery solves this problem. You get what you need from the manufacturer when you need it. You benefit by having parts or finished products arrive when you need them, so they don’t stack up and cost money before use. Your manufacturer benefits by reducing inventory storage costs — savings that may also benefit you.

3 Major Benefits of Just-In-Time Delivery

When looking at the practice of just-in-time delivery, there are three primary benefits you enjoy:

- Piece flow

- Quick die change

- Elimination of inventory

1. Piece Flow

Just-in-time disciplines work toward one-piece flow. Made-to-order manufacturing is ideal because workers are devoting line time to what truly needs their attention — the demands of their customers!

With a more streamlined process, issues are quickly detected at one of the production steps. This keeps your supply chain from dealing with defective products in large batches.

2. Quick Die Change

The single-minute exchange of dies (SMED) system significantly reduces setup time. Workers perform as many changeover steps as possible while the equipment is still running and all other steps are streamlined. The goal is to reduce changeover times to the “single” digits — in other words, less than 10 minutes.

3. Elimination of Inventory

It may seem more efficient for a metal shaping service to create 10,000 parts instead of 1,000. But the time it takes to make the other 9000 is the time your vendor could spend making a different part for you.

Instead of hoping for someone to buy the other 9,000 parts someday, your vendor should move on to make something it knows will be used. Otherwise, your vendor could be wasting your time — and money.

Want to learn more about how vendor managed inventory can help you? Check out our guide.

What to Look for When Considering A Roll Former’s Shipping Ability

You want the right product at the right price, delivered on time, and free from defects. Simple, right? However, many manufacturers struggle to hit all four points simultaneously. And consistently getting all four is harder still.

Here are four examples of how your roll forming manufacturer can improve on-time delivery and packaging:

Performance standards

Performance standards- Lean manufacturing methods

- Consolidating package costs

- Using roll forming efficiencies

1. Performance Standards

How seriously does your metal manufacturer take its lead time promises? Enough to monitor and measure performance closely?

Your supplier should be tracking its on-time delivery rate. The benchmark in metal manufacturing is 70%-80%.

Your supplier should also measure its parts-per-million (PPM) defect rates and have a plan for addressing quality control issues.

A contractor with poor numbers may be worth ditching if you’re in a highly competitive environment or require quick turnarounds.

2. Lean Manufacturing Methods

Using a kanban replenishment system helps prevent unnecessary deliveries and overcrowded manufacturing spaces for both the customer and supplier. Instead, you give your supplier regular counts of unopened bundles, and we replenish your stock to pre-agreed levels.

3. Consolidating Package Costs While Reducing/Eliminating In-Transit Damage

The packaging process is unique to each component and based on several factors, and your roll former should treat it as such. Your metal forming partner should spend money on packaging, period! Nothing is worse than damaged products in the field, which causes exponential problems for the entire supply chain.

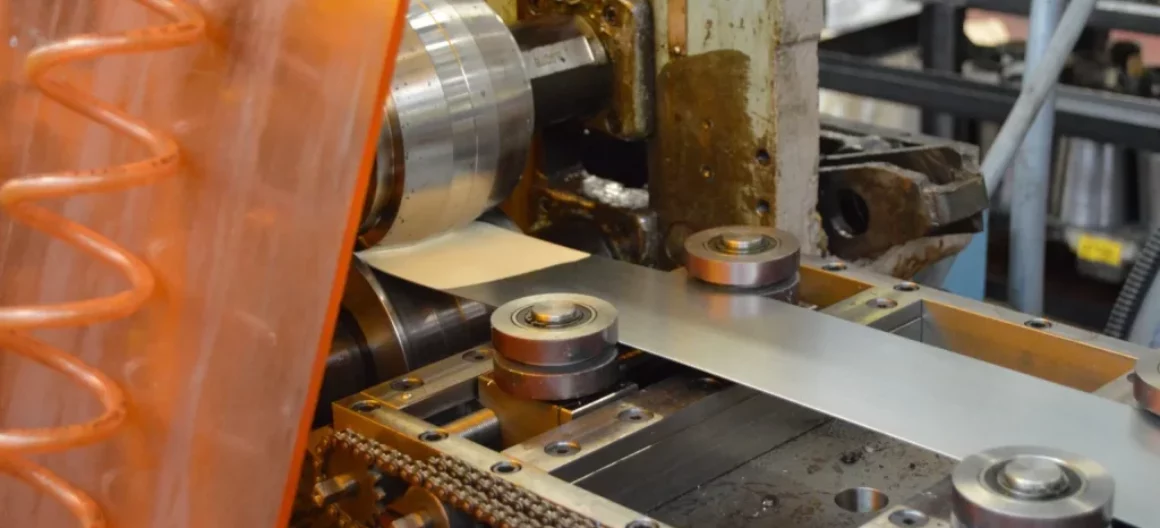

4. Using Roll Forming Efficiencies

If your vendor adds several easily repeatable features in-line, you reduce queuing and handling, which can boost delivery performance.

Consider Dual Sourcing Your Roll Forming For a More Efficient Supply Chain

Dual-sourcing is a great way to create an efficient supply chain. A quality domestic second source supplier will help you make sure your work is done on time so you can keep moving forward with no significant disruptions.

Grab a Quote!

Small to mid-sized domestic roll forming companies like Dahlstrom are great partners for your roll forming needs. Contact us for a quote today!