How Can a Roll Forming Company Help Your Industry?

You see roll formed parts everywhere, although you probably aren’t aware of it. If you spot a long, slender, metal part, it was probably made by a roll forming company. Examples of roll formed parts you see every day include:

You see roll formed parts everywhere, although you probably aren’t aware of it. If you spot a long, slender, metal part, it was probably made by a roll forming company. Examples of roll formed parts you see every day include:

- Guard rails on the side of the road

- Insulated shelving structure of the refrigerators in the grocery store

- Mounting structures for the solar panels you drive by on your way to work

- Stainless steel trim on the exterior of truck trailers you pass on the highway

Roll formed parts are also found in things you may never see and yet depend on, such as:

- Structural components in HVAC systems

- Shelving supports & cross members for warehouses

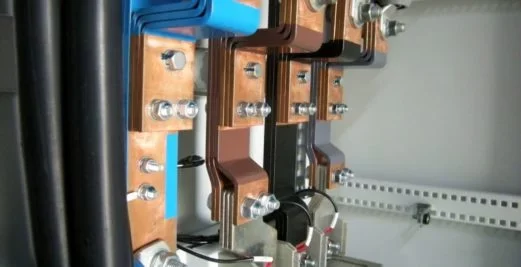

- Copper busbars & conductors for data centers

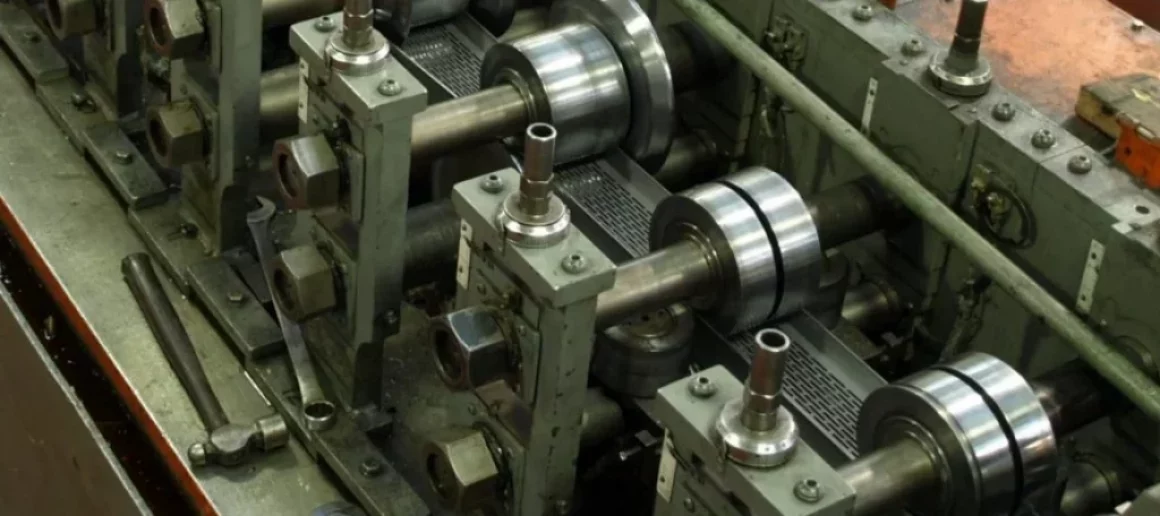

What can a roll forming company do for your industry? Whether your components require complex profiles, tricky hole patterns, pristine finishes, or basic shapes with no frills, metal roll forming is one of the most affordable fabrication processes.

Dahlstrom Roll Form has worked with several industries in our nearly 120-year history. Here’s a collection of the industries we work with most often and what we do for them:

Industries Served

Roll forming plays an important role in creating the interior and exterior of HVAC systems and commercial refrigeration. The tubing that makes up the refrigerant exchanger is made from roll formed copper. The kick plates and decorative trim on commercial refrigerators are also roll formed.

The power distribution system of a data center or a commercial retail center is a vital infrastructure. Custom roll formed parts are critical in both current-carrying (ex. – conductors) and non-current-carrying (ex. – wire raceways) equipment.

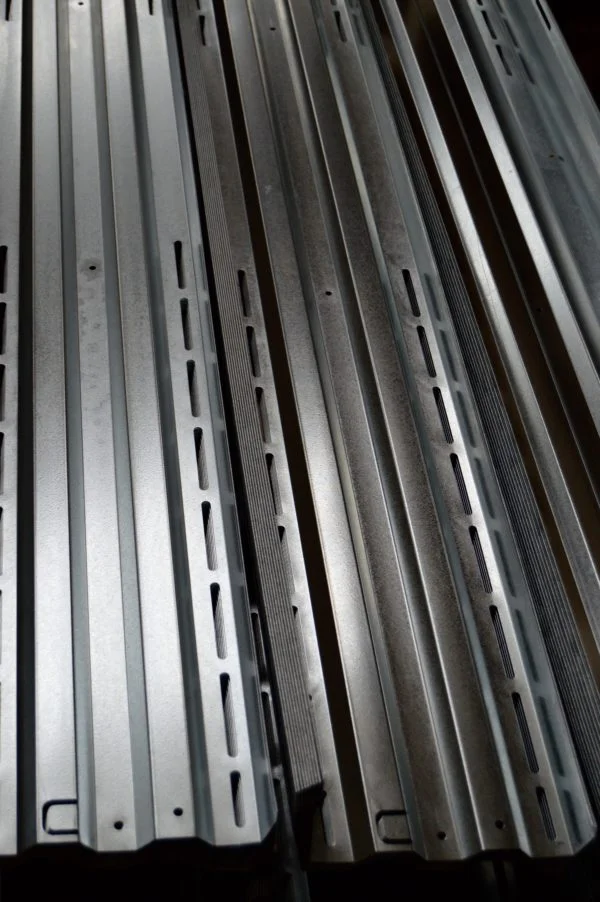

Warehouse distribution wouldn’t be nearly as efficient as it is today without roll forming. From shelving supports to automated pallet rails, roll formed parts are all over the warehouse.

Nearly every aspect of our lives involves computers. Whether for a small office server room to a large data center, data storage units like server racks are produced using roll formed parts.

The world depends on cargo trailers and trucks to deliver all sorts of goods. The manufacturers of these vehicles depend on roll forming to build the interior framing/skeleton of the cabs, decorative trim, and giant wheel fenders.

From elevator shaft tracking and structural cab components to interior decorative hardware and guide rails, roll forming is crucial to creating elevators and escalators.

The demand for green energy is on the rise, driving innovation in solar panel design and mounting products. Collaborate closely with your roll forming partner to create durable solar panel mounting systems that align with industry trends and stand the test of time.

Maximize production efficiency and cost-effectiveness by partnering with your roll forming supplier for inventory management, project scaling, custom designs, and more.